Publications

Please see my full list of publications.

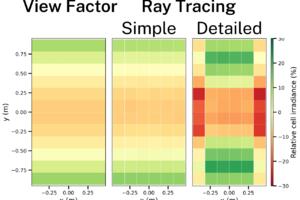

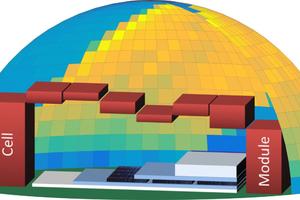

Comparison of view factor and ray tracing models

| Jun 03, 2024

Highlights • Comparative analysis of View Factor (VF) & Ray Tracing (RT) models for bifacial PV. • Both models perform similarly for front illumination, RT performs better for rear. • VF overestimates module rear irradiance by 6.7% due to frame & structure shading.

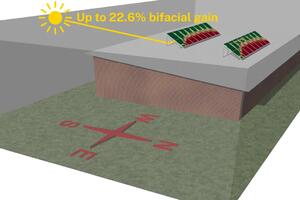

Bifacial gain of rooftop solar PV systems

| Dec 07, 2023

Highlights • Bifacial solar modules on rooftops offer up to 22.6% energy yield gains. • Rooftop reflectivity plays a crucial role in maximizing the bifacial potential. • Higher optimal tilt angles for bifacial modules, influenced by rooftop reflectivity. • Parallel intra-module interconnection supports achieving high bifacial yield gains. • Module-level optimizers enhance bifacial energy generation potential by up to 1.4%

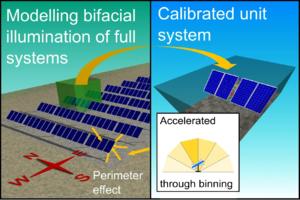

Accelerating ray tracing of real bifacial systems

| Dec 24, 2021

Bifacial photovoltaic solar panels convert light into electricity from both sides and are expected to dominate the market within a decade. Bifacial solar farm developers need accurate models of energy inputs, notably of rear illumination, to estimate annual energy yield and make accurate economic projections. Ray-tracing is the most suitable technique to simulate the complex optical interactions in single axis tracking bifacial PV farms but is computationally expensive. In this work, we accelerate Monte Carlo ray tracing of large solar systems by nearly 90% and validate our results with experimental data. We analyse the impact of the surrounding ground surface area and time-dependent ground reflection via calibrated unit systems. Overall, this work provides a basis for fast and accurate predictions of the annual energy input of real bifacial tracking PV systems. In turn this can lead to better system yield projections and contribute to lower risk for solar farm developers.

Solar module yield gains from structured ribbons

| Feb 25, 2021

We compare the effects of planar & triangular ribbons, light redirecting films, wires and a new proposed pentagonal ribbon geometry, in fixed optimal inclination, building-integrated (façade), and single-axis tracking installation scenarios of modules in portrait and landscape orientation. We conclude that to fully evaluate the effectiveness of a specific ribbon design, the annual energy yield must consider the angular irradiance distribution and weather conditions at a specific location, the installation scenario, and the module orientation.

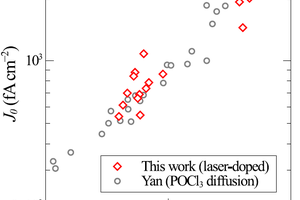

Laser contacts from POx/Al2O3 passivation stacks

| Aug 20, 2020

• n+ laser doping demonstrated from POx/Al2O3 passivation stacks on silicon. • Metallised J0 of 540 fA cm−2 for n+ laser-doped region with Rsheet of 39.5 Ω/□. • Consistent with values for POCl3 furnace diffusions, indicating minimal defects. • Same POx/Al2O3 stack provides J0 of 2.5 fA cm−2 on undiffused planar surfaces. • 23.6% simulated efficiency for laser-doped n-type PERL cell based on POx/Al2O3.

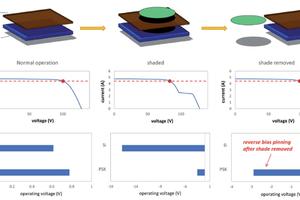

Destructive Reverse Bias in Perovskite Tandem Modules

| Jun 11, 2020

We demonstrate how perovskite hysteresis can result in permanent reductions in power output in perovskite/silicon tandem modules—including irreversible hotspot-induced damage—from only brief periods of shading.

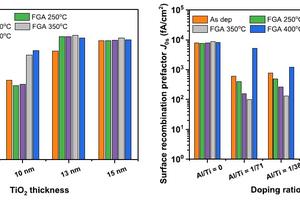

Impact of Al Doping on Surface Passivation of TiOx

| Apr 13, 2020

In this work, we find that the crystallization of ALD TiOx is very sensitive to the film’s thickness, where a small increase in TiOx thickness can trigger a phase change from amorphous TiOx into anatase, which causes a significant increase in J0s. More importantly, we demonstrate that the incorporation of Al ions into the TiOx films inhibits crystallization, which in turn retains excellent passivation for thicker TiOx.

Predicting realistic annual yield for solar modules

| Sep 12, 2019

• Optimizing module design for a maximum annual performance. • Detailed gain and loss analysis from cell under STC to module in real environment. • Understanding the impact of module material on the annual module yield. • Impact of angular light, temperatures, lower irradiances on module performance. • Impact of weather condition (ambient temperature, wind speed) on module performance.

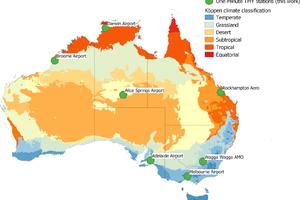

Methodology for Generating High Time Resolution Typical Meteorological Year Data for Accurate Photovoltaic Energy Yield Modelling

| Jul 30, 2019

Accurate energy yield prediction is of utmost importance for commercial scale photovoltaic systems. One key parameter crucial to the prediction accuracy is the quality of solar radiation data. Most energy yield prediction models rely on Typical Meteorological Year data with maximum temporal resolution of one hour. In this work we develop a methodology to generate Typical Meteorological Year data with much higher time resolution using gap filling methods that aim to maintain high-quality solar radiation data for photovoltaic yield modelling.

State-of-Energy-Research Conference (SoERC) 2019

| Jul 03, 2019

The SoERC conference is Australia's first research-only conference that highlights the latest advances in energy research. The conference takes place on 3rd and 4th July at the Australian National University, Canberra.

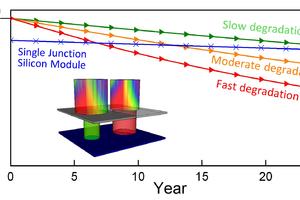

Lifetime energy yield and economic viability of perovskite/silicon tandem modules

| Apr 29, 2019

Impact of perovskite solar cell degradation on the lifetime energy yield and economic viability of perovskite/silicon tandem modules

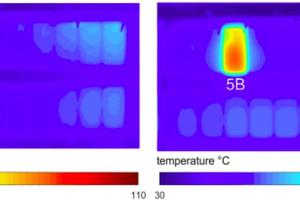

Analysis of Hotspots in Half Cell Modules Undetected by Current Test Standards

| Mar 07, 2019

Hotspots are a major source of failure for photovoltaic modules in the field. The current standard for module testing IEC 61215-2 can leave critical hotspots undetected in half-cut solar cell modules.